Higher Quality,

Higher Flow Rate,

Faster Regeneration

Demineralised water is used where a high level of water purity is required. Demin water is typically used for:

– Manufacturing processes where tap water could react with other ingredients.

– The pharmaceutical and cosmetics industries.

– In industrial processes for product cleaning and rinsing.

– In water cooling and car batteries.

A demin water plant is an efficient way to provide manufacturers with the pure water they need.

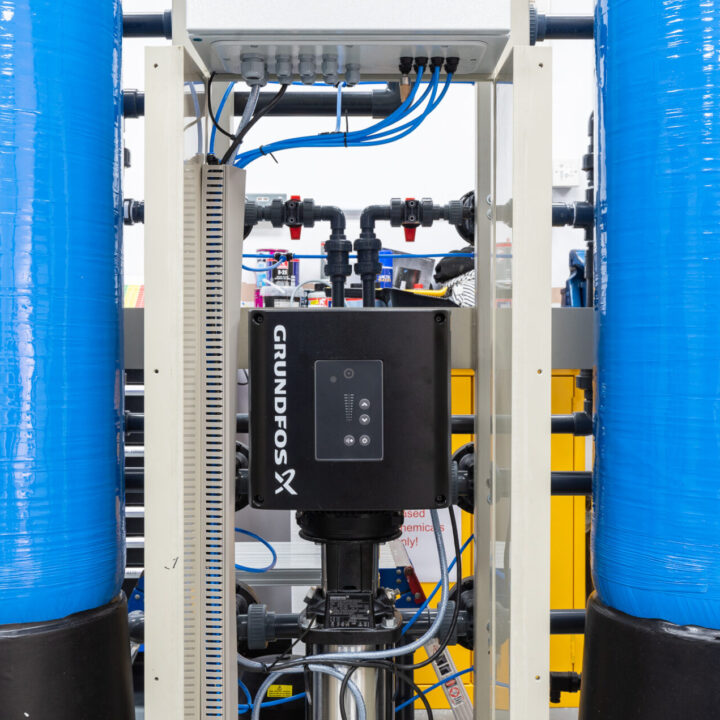

Our EX Power Denim Plant

- A faster supply of deionised water.

- Money savings with reduced downtime – around 20 mins

- No backup required and less storage

- Fully automatic with minimal operations

- A robust, long-lasting design.

How does a demin plant work?

Demin plants consist of two pressure vessels: one containing cation and the other containing anion exchange resins.

Raw water passes through the cation vessel first, where positively charged ions are chemically exchanged for hydrogen ions. Water then continues to the anion vessel where negatively charged ions are chemically exchanged for hydroxide ions. The hydrogen and hydroxide ions combine to create pure water.

Key Benefits

- Fast regeneration, typically less than 20 minutes so reduces downtime.

- High purity water levels can be achieved.

- Compact footprint.

- Minimal pre-treatment needed.

- Fully automatic with minimal operations.

Demin Regeneration

A demin plant needs to be regenerated with hydrochloric acid and sodium hydroxide. So, it is essential that COSHH Regulations are adhered to and any safety measures put in place.

A typical demin plant takes between 2 – 3 hours to regenerate. The regeneration of our demin plants takes approximately 20 minutes, meaning there’s very little downtime.

Our demineralisation plant, the EX Power, easily provides large volumes of pure water of less than 2 micro siemens, without the need for pre-treatment or post-treatment like Reverse Osmosis Plants. Since they are a stand-alone unit, they do not require a large amount of floor space either.

The drain should be capable of the maximum flow, as specified in the technical manual and withstanding 15% alkaline and acidic solutions. Waste water must be checked and the local water authority consulted before disposal. The customer is responsible for ensuring the effluent is within their consent to discharge levels.

Common Questions On Demineralisation Plants

How Easy Are They To Maintain?

Using a specialist service demin plant provider is essential to ensure that the plant is operating correctly and to prevent any breakdowns. In most cases, as long as these are serviced quarterly they can produce good quality water for years to come.

How Much Chemical Does The System Use?

This depends on how much the plant is used and how often a regeneration is required. As an example, the 10,000 litre Demin Plant we offer will use 25ltrs of Sodium Hydroxide and 23ltrs of Hydrachloric Acid everytime it regenerates. So, ensuring that the plant is sized correctly is key.

Is Any Pre-Treatment Required?

Assuming the system is running from mains water, the only pre-treatment normally required would be a carbon filter to protect the resin from chlorine damage and any sediment.