Get High Quality Pure

Water For Your Business

Save water and remove harsh chemicals from the water treatment process.

CEDI – Continuous Electronic Deionisation – units are purified water treatment modules used in the production of high-quality purified water for manufacturing processes.

Consistent, Safe, And Reliable Supply Of Pure Water

Manufacturers see significant cost savings over several years with continuous EDI systems, saving on the cost of chemicals and reduced downtime.

Which industries benefit?

– Energy

– Pharmaceutical

– Microelectronics

– Laboratories

– Automotive

– Manufacturing

– Food & Beverage

– Power

Key Benefits

- Cost-effective

- Safe process

- No harsh chemicals to store

- Small carbon footprint

- More consistent operation

- Minimal maintenance costs

Get The Exact System Your Business Needs

Our CEDI modules are the affordable alternative to other services out there. We don’t sell a one-size-fits-all package and you don’t pay more than you should. We design and build a CEDI system specifically for your business along with suitable pre-treatment (generally an RO unit). We could possibly incorporate your existing water treatment equipment and design a process to save your business ongoing costs.

How Does It Work?

Continuous EDI systems work by passing a DC voltage through a module containing Anion and Cation resin. Membranes selectively allow positively and negatively charged ions to pass through streams of good quality water (termed dilute) and wastewater (termed concentrate or reject). The water splits into a highly purified stream and a waste stream.

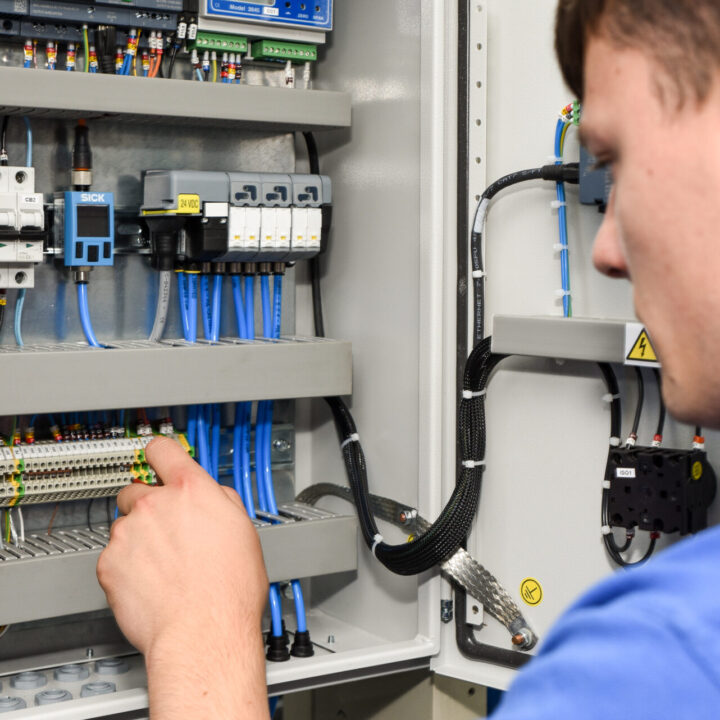

Installation And

Maintenance

CEDI modules should be installed indoors away from direct sunlight and temperatures should not exceed 113°F (45°C). The systems require very little maintenance, and we provide equipment servicing to ensure water purity stays at the required level.

Common Questions On CEDI Units

What Applications Would Be Suitable For CEDI?

CEDI units are most commonly used in pharmaceutical applications where a constant, high purity supply is required. They can also be used in laboratories for testing in a controlled environment.